Wave-making resistance is a form of drag that affects surface watercraft, such as boats and ships, and reflects the energy required to push the water out of the way of the hull. This energy goes into creating the wave.

Physics

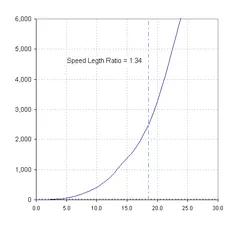

Graph of power versus speed for a displacement hull, with a mark at a speed–length ratio of 1.34

For small displacement hulls, such as sailboats or rowboats, wave-making resistance is the major source of the marine vessel drag.

A salient property of water waves is dispersiveness; i.e., the longer the wave, the faster it moves. Waves generated by a ship are affected by her geometry and speed, and most of the energy given by the ship for making waves is transferred to water through the bow and stern parts. Simply speaking, these two wave systems, i.e., bow and stern waves, interact with each other, and the resulting waves are responsible for the resistance.

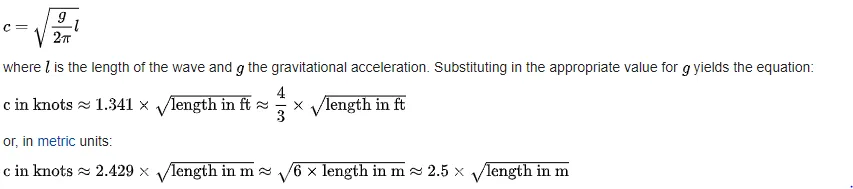

The phase speed of deepwater waves is proportional to the square root of the wavelength of the generated waves, and the length of a ship causes the difference in phases of waves generated by bow and stern parts. Thus, there is a direct relationship between the waterline length and the magnitude of the wave-making resistance. Wave propagation speed, which means the same thing as the phase speed of deepwater wave, is independent of length of the hull causing the wave, but dependent of the speed of the hull instead.

A simple way of considering wave-making resistance is to look at the hull in relation to bow and stern waves. If the length of a ship is half the length of the waves generated, the resulting wave will be very small due to cancellation, and if the length is the same as the wavelength, the wave will be large due to enhancement.

These values, 1.34, 2.5 and very easy 6, are often used in the hull speed rule of thumb used to compare potential speeds of displacement hulls, and this relationship is also fundamental to the Froude number, used in the comparison of different scales of watercraft.

When the vessel exceeds a “speed–length ratio” (speed in knots divided by square root of length in feet) of 0.94, it starts to outrun most of its bow wave, the hull actually settles slightly in the water as it is now only supported by two wave peaks. As the vessel exceeds a speed-length ratio of 1.34, the wavelength is now longer than the hull, and the stern is no longer supported by the wake, causing the stern to squat, and the bow to rise. The hull is now starting to climb its own bow wave, and resistance begins to increase at a very high rate. While it is possible to drive a displacement hull faster than a speed-length ratio of 1.34, it is prohibitively expensive to do so. Most large vessels operate at speed-length ratios well below that level, at speed-length ratios of under 1.0.

Ways of reducing wave-making resistance

Since wave-making resistance is based on the energy required to push the water out of the way of the hull, there are a number of ways that this can be minimized.

Reduced displacement

Reducing the displacement of the craft, by eliminating excess weight, is the most straightforward way to reduce the wave making drag. Another way is to shape the hull so as to generate lift as it moves through the water. Semi-displacement hulls and planing hulls do this, and they are able to break through the hull speed barrier and transition into a realm where drag increases at a much lower rate. The disadvantage of this is that planing is only practical on smaller vessels, with high power-to-weight ratios, such as motorboats. It is not a practical solution for a large vessel such as a supertanker.

Fine entry

A hull with a blunt bow has to push the water away very quickly to pass through, and this high acceleration requires large amounts of energy. By using a fine bow, with a sharper angle that pushes the water out of the way more gradually, the amount of energy required to displace the water will be less. A modern variation is the wave-piercing design. The total amount of water to be displaced by a moving hull, and thus causing wave making drag, is the cross sectional area of the hull times distance the hull travels, and will not remain the same when prismatic coefficient is increased for the same lwl and same displacement and same speed.

Bulbous bow

A special type of bow, called a bulbous bow, is often used on large power vessels to reduce wave-making drag. The bulb alters the waves generated by the hull, by changing the pressure distribution ahead of the bow. Because of the nature of its destructive interference with the bow wave, there is a limited range of vessel speeds over which it is effective. A bulbous bow must be properly designed to mitigate the wave-making resistance of a particular hull over a particular range of speeds. A bulb that works for one vessel’s hull shape and one range of speeds could be detrimental to a different hull shape or a different speed range. Proper design and knowledge of a ship’s intended operating speeds and conditions is therefore necessary when designing a bulbous bow.

Hull form filtering

If the hull is designed to operate at speeds substantially lower than hull speed then it is possible to refine the hull shape along its length to reduce wave resistance at one speed. This is practical only where the block coefficient of the hull is not a significant issue.

Semi-displacement and planing hulls

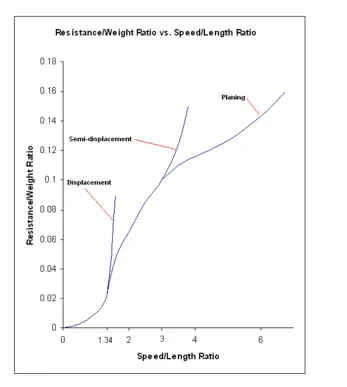

A graph showing resistance–weight ratio as a function of speed–length ratio for displacement, semi-displacement, and planing hulls

Since semi-displacement and planing hulls generate a significant amount of lift in operation, they are capable of breaking the barrier of the wave propagation speed and operating in realms of much lower drag, but to do this they must be capable of first pushing past that speed, which requires significant power. This stage is called the transition stage and at this stage the rate of wave-making resistance is the highest. Once the hull gets over the hump of the bow wave, the rate of increase of the wave drag will start to reduce significantly. The planing hull will rise up clearing its stern off the water and its trim will be high. Underwater part of the planing hull will be small during the planing regime.

A qualitative interpretation of the wave resistance plot is that a displacement hull resonates with a wave that has a crest near its bow and a trough near its stern, because the water is pushed away at the bow and pulled back at the stern. A planing hull simply pushed down on the water under it, so it resonates with a wave that has a trough under it. If it has about twice the length it will therefore have only square root or 1.4 times the speed. In practice most planing hulls usually move much faster than that. At four times hull speed the wavelength is already 16 times longer than the hull.