The term cast iron, like the term steel, identifies a large family of ferrous alloys. Cast irons are multicomponent ferrous alloys. They contain major (iron, carbon, silicon), minor (<0.01%), and often alloying (>0.01%) elements. Cast iron has higher carbon and silicon contents than steel. Because of the higher carbon content, the structure of cast iron, as opposed to that of steel, exhibits a rich carbon phase. Depending primarily in composition, cooling rate and melt treatment, cast iron can solidify according to the thermodynamically metastable Fe-Fe3C system or the stable Fe-Gr system.

The term cast iron, like the term steel, identifies a large family of ferrous alloys. Cast irons are multicomponent ferrous alloys. They contain major (iron, carbon, silicon), minor (<0.01%), and often alloying (>0.01%) elements.

Cast iron has higher carbon and silicon contents than steel. Because of the higher carbon content, the structure of cast iron, as opposed to that of steel, exhibits a rich carbon phase. Depending primarily on composition, cooling rate and melt treatment, cast iron can solidify according to the thermodynamically metastable Fe-Fe3C system or the stable Fe-Gr system.

When the metastable path is followed, the rich carbon phase in the eutectic is the iron carbide; when the stable solidification path is followed, the rich carbon phase is graphite. Referring only to the binary Fe-Fe3C or Fe-Gr system, cast iron can be defined as an iron-carbon alloy with more than 2% C. Important notice is that silicon and other alloying elements may considerably change the maximum solubility of carbon in austenite (g). Therefore, in exceptional cases, alloys with less than 2% C can solidify with a eutectic structure and therefore still belong to the family of cast iron.

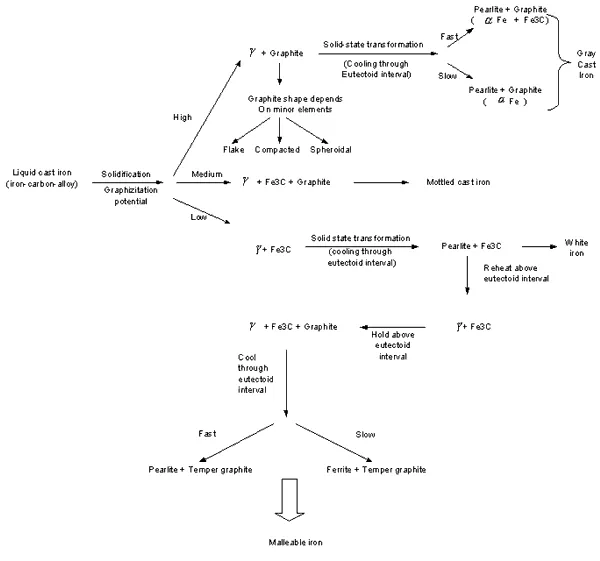

The formation of stable or metastable eutectic is a function of many factors including the nucleation potential of the liquid, chemical composition, and cooling rate. The first two factors determine the graphitization potential of the iron. A high graphitization potential will result in irons with graphite as the rich carbon phase, while a low graphitization potential will result in irons with iron carbide.

The two basic types of eutectics – the stable austenite-graphite or the metastable austenite-iron carbide (Fe3C) – have wide differences in their mechanical properties, such as strength, hardness, toughness, and ductility. Therefore, the basic scope of the metallurgical processing of cast iron is to manipulate the type, amount, and morphology of the eutectic in order to achieve the desired mechanical properties.

Classification

Historically, the first classification of cast iron was based on its fracture. Two types of iron were initially recognised:

· White iron: Exhibits a white, crystalline fracture surface because fracture occurs along the iron carbide plates; it is the result of metastable solidification (Fe3C eutectic)

· Gray iron: Exhibits a gray fracture surface because fracture occurs along the graphite plates (flakes); it is the result of stable solidification (Gr eutectic).

With the advent of metallography, and as the body of knowledge pertinent to cast iron increased, other classifications based on microstructural features became possible:

· Graphite shape: Lamellar (flake) graphite (FG), spheroidal (nodular) graphite (SG), compacted (vermicular) graphite (CG), and temper graphite (TG); temper graphite results from ? solid-state reaction (malleabilization.)

· Matrix: Ferritic, pearlitic, austenitic, martensitic, bainitic (austempered).

This classification is seldom used by the floor foundryman. The most widely used terminology is the commercial one. A first division can be made in two categories:

· Common cast irons: For general-purpose applications, they are unalloyed or low alloyed

· Special cast irons: For special applications, generally high alloyed.

The correspondence between commercial and microstructural classification, as well as the final processing stage in obtaining common cast irons, is given in Fig. 2.

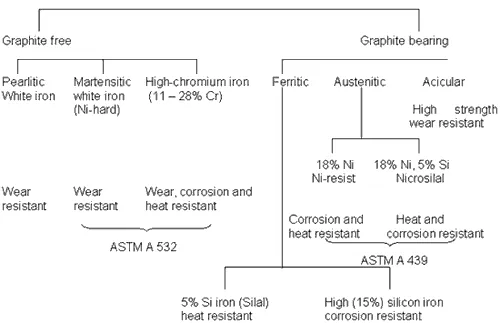

Special cast irons differ from the common cast irons mainly in the higher content of alloying elements (>3%), which promote microstructures having special properties for elevated-temperature applications, corrosion resistance, and wear resistance. A classification of the main types of special cast irons is shown in Fig. 1.

Fig. 1. Classification of special high – alloy cast iron

Fig.2. Basic microstructures and processing for obtaining common commercial cast irons