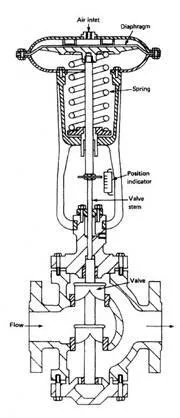

Many pneumatic devices use a nozzle and flapper system to give a variation in the compressed air signal.A typical pneumatic control valve is shown in Figure . It can be considered as made up of two parts—the actuator and the valve. In the arrangement shown a flexible diaphragm forms a pressure tight chamber in the upper half of the actuator and the controller signal is fed in.

Movement of the diaphragm results in a movement of the valve spindle and the valve. The diaphragm movement is opposed by a spring and is usually arranged so that the variation of controller output corresponds to full travel of the valve.

The valve body is arranged to fit into the particular pipeline and houses the valve and seat assembly. Valve operation may be direct acting where increasing pressure on the diaphragm closes the valve.

A reverse acting valve opens as pressure on the diaphragm increases. The diaphragm movement is opposed by a spring which will close or open the valve in the event of air supply failure depending upon the action of the valve.

Fig: A pneumatically controlled valve

The valve disc or plug may be single or double seated and have any of a variety of shapes. The various shapes and types are chosen according to the type of control required and the relationship between valve lift and liquid flow.

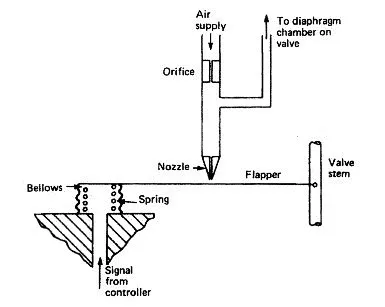

A non-adjustable gland arrangement is usual. Inverted V-ring packing is used to minimise the friction against the moving spindle. In order to achieve accurate valve disc positioning and overcome the effects of friction and unbalanced forces a valve positioner may be used. The operating principle is shown in Figure .

The controller signal acts on a bellows which will move the flapper in relation to the nozzle. This movement will alter the air pressure on the diaphragm which is supplied via an orifice from a constant pressure supply. The diaphragm movement will move the valve spindle and also the flapper. An equilibrium position will be set up when the valve disc is correctly positioned. This arrangement enables the use of a separate power source to actuate the valve.

Fig: Valve positioner

Actuator operation

The control signal to a correcting unit may be pneumatic, electric or hydraulic. The actuating power may also be any one of these three and not necessarily the same as the control medium. Electrical control signals are usually of small voltage or current values which are unable to effect actuator movement. Pneumatic or hydraulic power would then be used for actuator operation.

A separate pneumatic power supply may be used even when the control signal is pneumatic, as described in the previous section. Hydraulic actuator power is used where large or out of balance forces occur or when the correcting unit is of large dimensions itself. Hydraulic control with separate hydraulic actuation is a feature of some types of steering gear.