On-Off control is the simplest form of feedback control. An on-off controller simply drives the manipulated variable from fully closed to fully open depending on the position of the controlled variable relative to the setpoint. A common example of on-off control is the temperature control in a domestic heating system. When the temperature is below the thermostat setpoint the heating system is switched on and when the temperature is above the setpoint the heating switches off.

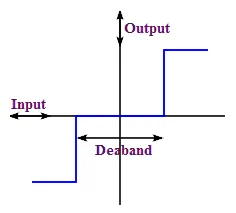

There is, however, a bit of subtlety applied in practical on-off systems. If the heating switches on and off the instant the measured temperature crossed the setpoint then the system would chatter – repeatedly switch on and off at very high frequency. If this happened the boiler wouldn’t last very long! To avoid chattering, practical on-off controllers usually have a deadband around the setpoint. When the measured value lies within this dead-band the controller does nothing – its only when the value moves outside that action is taken. The effect of this is to introduce continuous oscillation in the value of the controlled variable – the large the dead-band the higher the amplitude and lower the frequency.

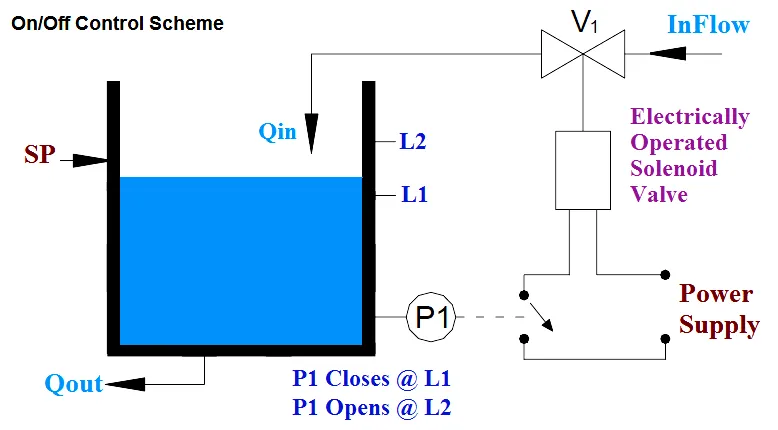

Example:

The valve in the inflow line to the system is an electrically operated solenoid valve. (Remember an electrically operated solenoid valve has only two operating positions – fully open or fully closed.) Assume that under initial conditions with a demand on the system the level will start to fall and V1 will have to be opened to provide an inflow. This can easily be achieved by mounting a differential pressure switch, P1 at the bottom of the tank to operate when the level falls to L1. When the level is at L1 the liquid will be height h1 above switch.

The pressure at the switch will be P1 = ρgh1.

ρ – the mass density of the liquid

g – the acceleration due to gravity

h1 – the height of the liquid

The resulting switch closure can energize the solenoid valve V1 causing an inflow to the tank. Assuming the valve is correctly sized, this will cause a rise in the level back towards the setpoint.

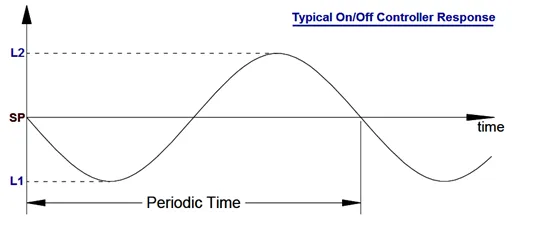

In order to arrest the rise in level the built in differential feature of the switch can be employed to de-energize the solenoid valve when level L2 is reached. This system will achieve a mean level in the tank about the desired setpoint. This method is known as ON/OFF control. Clearly it is impossible to maintain the system at the setpoint since there must be a difference in the operating levels L1 and L2 as the valve can only be energized or de-energized. It is often counter productive to try to reduce the differential between L1 and L2 to too small a value as this will result in excessive cycling, and hence wear, of the valve. Usual practice is to control with a deadband about the setpoint as shown in Below Figure.

The sinusoidal cycling is typical of on/off control. on/off control can be used to advantage on a sluggish system, i.e., where the periodic time is large. Typical uses in electric heater controls. If fine control is required a simple on/off control system is inadequate.

Following are a few aspects of On-Off Control that you should keep in mind when considering it for commercial application:

§ An Open or Shut Case

As its name implies, On-Off Control assigns the Controller Output (CO) to one of two positions such that the final control element (FCE) is either fully open or fully closed. Unlike intermediate value or PID control, there is no in between. Most industrial processes require greater latitude when it comes to adjusting the CO’s position.

§ Ups and Downs

On-Off Control can result in excessive variability as the controller has so few options for maintaining Set Point. A process equipped with On-Off Control will constantly overshoot its Set Point and cycle as a result. The work demanded of the FCE regularly accelerates the time to failure and increases maintenance costs.

§ Setting Boundaries

Deadband is a range of operation around the Set Point and within which the controller’s action will not change. On-Off Control with Deadband establishes upper and lower boundaries that are acceptable to the control loop’s operation. While Deadband’s “cushion” reduces wear on the FCE, variability remains within the process which can present challenges for other downstream processes.