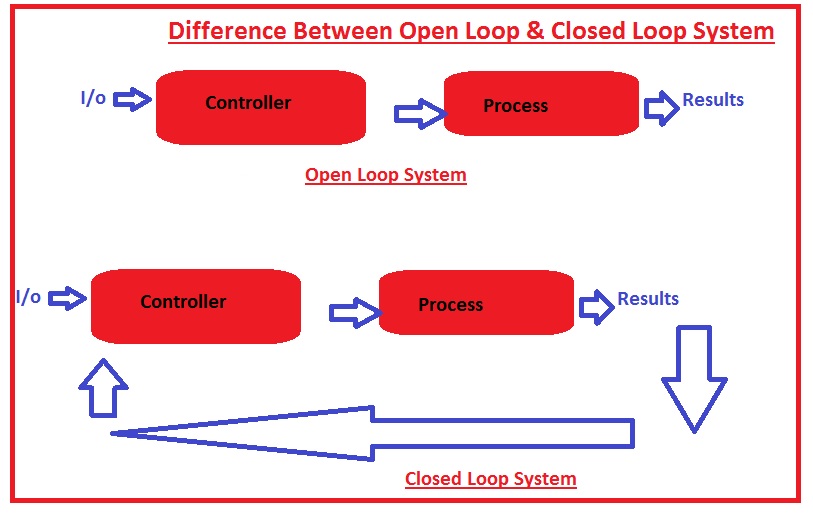

One of the significant difference between the open loop and closed loop control system is that in an open loop system the desired output does not depend on the control action. While in the closed loop system the desired output depends on the control action of the system. The other differences between the open and closed loop system are shown below in the comparison chart.

Content: Open Loop Vs Closed Loop System

1. Comparison Chart

2. Definition

3. Key Differences

4. Conclusion

Comparison Chart

| Basis For Comparison | Open Loop System | Closed Loop System |

| Definition | The system whose control action is free from the output is known as the open loop control system. | In closed loop, the output depends on the control action of the system. |

| Other Name | Non-feedback System | Feedback System |

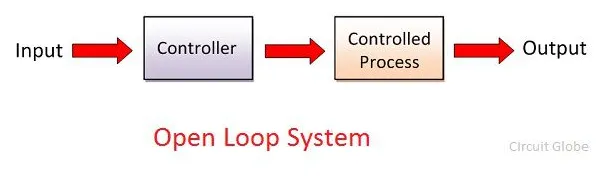

| Components | Controller and Controlled Process. | Amplifier, Controller, Controlled Process, Feedback. |

| Construction | Simple | Complex |

| Reliability | Non-reliable | Reliable |

| Accuracy | Depends on calibration | Accurate because of feedback. |

| Stability | Stable | Less Stable |

| Optimization | Not-Possible | Possible |

| Response | Fast | Slow |

| Calibration | Difficult | Easy |

| System Disturbance | Affected | Not-affected |

| Linearity | Non-linear | Linear |

| Examples | Traffic light, automatic washing machine, immersion rod, TV remote etc. | Air conditioner, temperature control system, speed and pressure control system, refrigerator, toaster. |

Open Loop Control System

In open loop control system, the output does not affect the control action of the system. In other words, the system whose working depends on time is known as the open loop control system. The open loop system is free from the feedback. Let’s understand this with the help of the few examples.

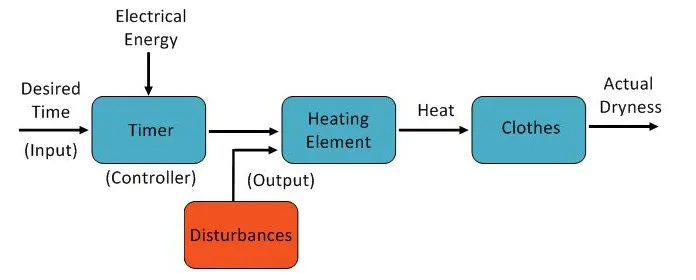

Example 1: Consider the clothes dryer whose control action is done manually by the operator. Depending on the wetness of the clothes suppose the operator set the timer for 30 minutes. After 30 minutes the timer will stop even after the clothes are wet.

The dryer stops working even if the desired output is not obtained. This shows that the system has no feedback. Here clothes dryer is the example of the open loop system and the timer is the controller of the system.

Example 2: The automatic washing machine is the example of the open loop system. The operator manually sets the operating time of the machine. The machine stops operating after the set time, even the desire cleanliness of clothes are not obtained. This happens because the machine has no feedback system which signals the control action of the system for desired output.

The open loop system is simple, require less maintenance. Also, it is fast in operation and very economical. But the accuracy of the system is less, and it is less reliable.

Closed Loop Control System

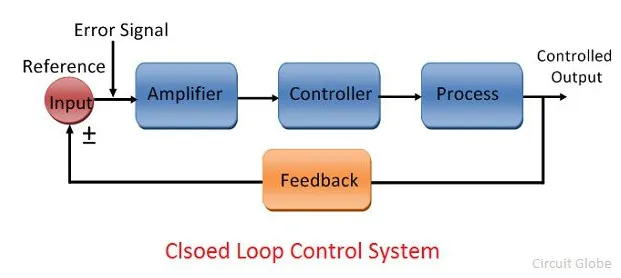

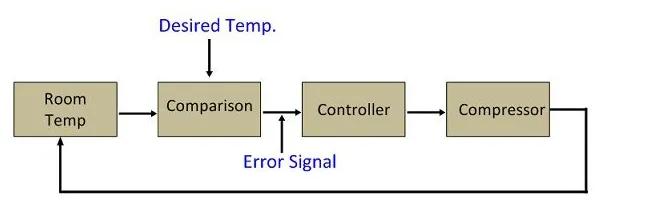

The closed-loop control system means the output of the system depends on their input. The system has one or more feedback loops between its output and input. The closed-loop system design in such a way that they automatically provide the desired output by comparing it with the actual input. The closed-loop system generates the error signal which is the difference between the input and output.

Example 1: Suppose in the above example of closed dryer we are using the transducer which senses the dryness of the clothes and provides the feedback signal to the controller relating to dryness. Here the dryness is the output of the system. The sensor act as a feedback of the system. The sensor gives the signal to the controller of the machine, and hence the dryer provides the desired output.

Example 2: The air conditioner is the example of the closed-loop system. The air conditioner regulates the temperature by comparing it with the surrounding temperature. The comparison of temperature is done with the help of the thermostat. When the AC provides the error signal which is the difference between the surrounding temperature and room temperature the thermostats turn on or off the compressor.

The closed loop system is more reliable and accurate. But this system is very expensive and requires high maintenance.

Key Differences between Open Loop and Closed Loop System

1. The open loop system means the output of the system is free from their input. In the closed-loop system, the desired output depends on their input.

2. The open loop system is called the non-feedback system while the closed loop is the feedback system.

3. The control and controlled process are the two components of the open loop system. The closed loop requires some components likes an amplifier, controller, controlled process, feedback system etc.

4. The construction of systems is easy because few elements are used in the system. The construction of the closed-loop system is quite difficult.

5. The open loop system is not reliable whereas the closed-loop system is reliable.

6. The accuracy of the system is less as compared to the closed-loop system.

7. The open loop system is more stable as compared to a closed loop system. Here the word stable means the output of the system remains constant even after the disturbances.

8. The open loop system is not optimized, whereas the closed-loop system is optimized.

9. The open loop system gives the fast response, whereas the closed loop system gives the slow response.

10. The calibration of open loop system is difficult as compared to the closed-loop system.

11. In an open loop system, the disturbance affected the output, whereas in a closed loop system the output is not much affected by the disturbances.

12. The output control system has a non-linear response, whereas the input control system has linear responses.

13. The traffic light, automatic washing machine, etc. are the examples of the output system, whereas the temperature controller, toaster etc. are the examples of the closed-loop system.

Conclusion

The open loop and control loop are the two types of control system. The open loop system works on input, and it is simple in construction while the closed loop system is complex and their output depends on the input.

Comments are closed