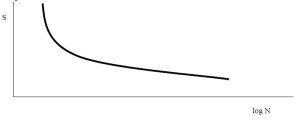

Fatigue is the failure of a component under fluctuating stress, and as such all components which are exposed to alternating stress must ensure that either it has a defined service lifetime or that the applied level of fluctuating stress is below the fatigue limit for that material. Materials can be tested to find the relationship between the applied stress (S) and the number of stress cycles (N). These tests produce the characteristic S-N curves as reproduced below, and attempt to define the number of cycles to failure.

For the two variables of S and N, it can be seen that if the level of stress increases, then the time to failure is reduced, and the component will fail earlier. Similarly if the component is operated for too many cycles, then it will also fail at the normal level of applied stress.

Material Defect and Fatigue Failure

When a material defect occurs, then the level of stress in a localised area around that defect will rise. The level of the stress increase will be dictated by the position of the crack, its orientation to the applied stress, and the level of applied stress in the material. Normally any material defect, which increases the stress level, will cause the component to fail at an earlier stage.

Fatigue Failure on a Bedplate Transverse Girder

The following factors would increase the stress imposed on the girder, and would therefore increase the likelihood of cracking:

1. Engine operating with excessive cylinder pressures

2. Tie bolt tension incorrect, either too high or low

3. Jacking bolts over-tensioned on the Sulzer type slow speed engines

4. Crankshaft alignment poor, either due to local bearing failure or poor chock support, or vessel hull deformation

To minimise these effects the following routine checks should be carried out:

1. Regular monthly checks of engine load using power cards, and measuring the cylinder peak pressures using peak pressure indicators or power cards

2. Regular yearly checks of the tie bolt tension

3. Regular yearly checks of the tension of the main bearing jack bolts

4. Regular three monthly checks of crankshaft alignment.

5. By preventing an increase the applied stress on the girder, the likelihood of cracking is greatly reduced, however regular visual checks should also be carried out beneath the main bearing.