The purpose with the lambda controller is to prevent injection of more fuel in the combustion chamber of an auxiliary engine on the ship, than can be burned during a momentary load increase. This is carried out by controlling the relation between the fuel index and the charge air pressure. The Lambda controller is also used as stop cylinder.

Advantages of Lambda Controller

The lambda controller has the following advantages:

1. Reduction of visible smoke in case of sudden momentary load increases on auxiliary engines.

2. Improved load ability.

3. Less fouling of the engine’s exhaust gas ways.

4. Limitation of fuel oil index during starting procedure.

Principle of Lambda Controller

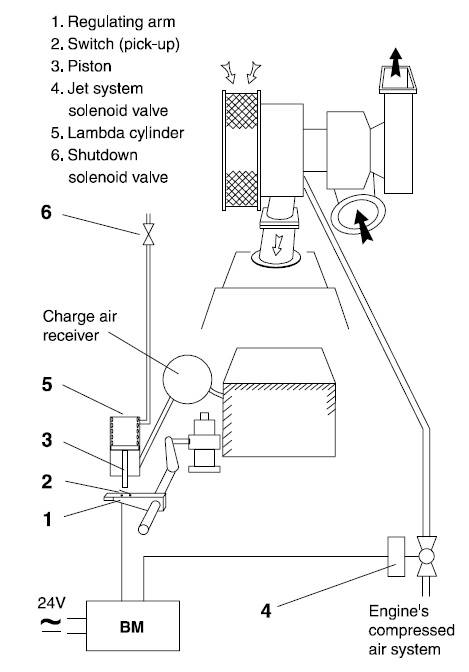

Figure above illustrates the controller’s operation mode. In case of a momentary load increase, the regulating device will increase the index on the injection pumps and hereby the regulator arm (1) is turned, the switch (2) will touch the piston arm (3) and be pushedb downwards, whereby the electrical circuit will be closed.

Thus the solenoid valve (4) opens. This valve is supplied with compressed air and the same is supplied to assist the turbocharger. When this jet system is activated, the turbocharger accelerates and increases the charge air pressure, thereby pressing the piston (3) backwards in the lambda cylinder (5). When the lambda ratio is satisfactory, the jet system will be deactivated. At a 50% load change the system will be activated for about 3-8 seconds.

If the system is activated more than 10 seconds, the solenoid valve will be shut off and there will be a remote signal alarm for “jet system failure”.

Fuel Oil Limiting During Start Procedure

During the start procedure the lambda controller is used as an index limiter. Hereby heavy smoke formation is prevented during start procedure and further the regulating device cannot over-react. The jet system is blocked during the starting procedure until the engine has reached about 110 RPM.