In this topic we will learn about one very important component namely the deck water seal which acts like a one way valve allowing inert gases to pass over but preventing any backflow of cargo gases to the Inert Gas (IG) system of the ship

Introduction

In the last article we studied about the inert gas blowers which pass on the inert gas from the scrubber and demister tower for introduction into the distribution piping of the IG system. If you remember the article giving the overall diagram of the IG system the gas is now ready to pass on from the safe zone to the hazardous zone on the deck. Therefore a system needs to be in place which prevents any backflow of cargo gases to the safe zone and it is here that the deck water seal comes into the picture

The Deck Water Seal

Before studying the deck water seal let me also tell you that there is an IG pressure regulating valve which returns any excess inert gas to the scrubber and then the gas passes to the deck water seal going through the vent valve. The vent valve should be opened when the main IG plant is shut down in order to prevent any backflow or pressure build up in the pipelines.

The deck water seal is the main safeguard against the reverse flow of gases from the distribution system to the IG plant. Deck water seals come in three variants known as wet type seal, semi-wet seal and dry type seal. This distinction is based on the manner in which they achieve their purpose and a brief description of each is as follows.

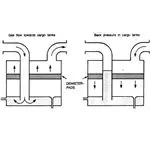

Wet Type Dry Water Seal

The picture below shows the construction of a wet type deck water seal and its functioning. Basically it consists of a chamber semi-filled with water and two pipes for inlet and outlet of flue gases while another two small pipes denote inlet and outlet for sealing water. There is a demister pad to remove water droplets from gas. The operation of this device is pretty simple and the two diagrams shows conditions where the inert gas is flowing from the plant to the distribution area and the right hand side showing a condition where back pressure tends to push cargo gases into the IG system and is prevented by the water seal.

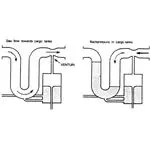

Semi Dry Type Deck Water Seal

The construction of this type of seal as well as the functioning under both conditions is shown in the diagram below. The main difference with the previous type of seal is that it uses venture action to draw water when there are chances of backflow of the gases thus reducing if not completely eliminating water carry over to the cargo tanks.

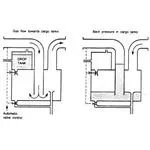

Dry Type Deck Water Seal

This seal totally eliminates any water carry over and uses automated valve control to deliver water to the seal in case there is any back flow but the only disadvantage is that if automation system fails then there is a danger of blow back of cargo gases.

Just keep in mind that only one of these seals is used, and in addition to this deck seal there is a mechanical non return valve for extra safety in the pipeline as well.