After installation of the bulkheads, they are to be tested for their integrity and water tightness. Since it is not feasible to fill all the cargo holds or compartments with water for this purpose, the test is done by a pressure hose. In this process, the bulkhead is subjected to a prerequisite water pressure from a hose for a fixed period of time, after which, the structural integrity of the bulkhead is inspected (checks are done for buckling and other deformations). Leak tests can also be done by pressurising the air in a compartment and checking for leakage of air to the other compartment.

Watertight Doors

Intactness is the primary purpose to be maintained by a watertight bulkhead. But in most ships, there are situations unavoidable where access from one compartment to another is a necessity. For example, an under-deck access from one cargo hold to another or from one compartment to another in case of passenger ships. In most ships, access to the shaft tunnel is necessary especially to monitor shaft oil temperatures or for repairs in the region. This purpose is solved by the use of watertight doors.

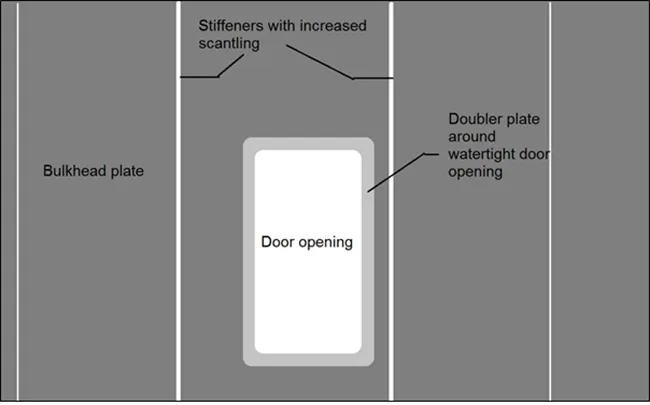

The bulkhead panel is usually cut out in a rectangular shape accommodating a watertight door. However, special incorporations are made in the structural design of the region around the door opening:

· The dimensions of the opening are kept to the minimum.

· An opening results in a major structural discontinuity, resulting in stress concentration around the opening. To maintain stress levels below safety limits, the opening is strengthened by doubler plates to increase the thickness of the bulkhead plate around the opening.

· If a vertical bulkhead stiffener comes in the way of the opening, it is terminated at the upper and lower edges of the opening. However, designers might choose to increase the stiffener spacing to avoid this. In that case, the scantling of the stiffeners adjacent to the opening are increased from the remaining stiffeners.

Figure 6: Opening for watertight door on a bulkhead plate.

Watertight doors are usually hydraulically or electrically operated, and are either horizontally or vertically sliding. The reason why swinging doors are not provided in watertight bulkheads is because it would be impossible to close a swinging door in case of flooding. It must be easily operable even when the ship has listed to 15 degrees to either side, and the control system should be so designed that the door can be operated from the vicinity as well as remotely, i.e. from a position above the bulkhead deck. In all ships, visual indicators are provided at the remote control location to denote whether the door is open or closed.

Watertight doors are also subjected to pressure tests after installation to check for their structural integrity at design hydrostatic pressure in case of complete flooding up to the bulkhead deck.