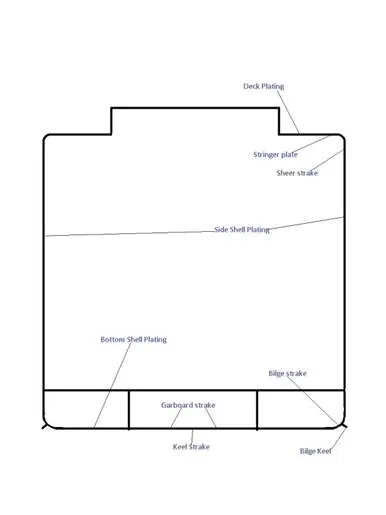

Shell and Deck Plating

The shell plating forms the watertight skin of the ship and at the same time, contributes to the longitudinal strength and resists vertical shear forces. Internal strengthening of the shell plating may be both transverse and longitudinal.

The bottom and side shell plating consists of a series of flat and curved steel plates butt welded together. The vertical welded joints are referred to as ‘butts’ and the horizontal welded joints as ‘seams’. Stiffening members both longitudinal and transverse are generally welded to the shell.

Bottom shell plating

Throughout the length of the ship the width and thickness of the keel plate remain constant where a flat plate keel is fitted. Its thickness is never less than that of the adjoining bottom plating. Keel strake is on the center line.

Strakes of bottom plating to the bilges have their greatest thickness over the 40% of the ship’s length amidships, where the bending stresses are highest. The bottom plating then tapers to a lesser thickness at the ends of the ship, apart from increased thickness requirements in way of the pounding region.

Side shell plating

As with the bottom shell plating, the greater thickness of the side shell plating is maintained within 40% of the vessel’s midship length and then tapers to the rule thickness at the ends. The thickness may be increased in regions where high vertical shear stresses occur, usually in way of transverse bulkheads in a vessel permitted to carry heavy cargoes with some holds empty. There is also a thickness increase at the stern frame connection, at any shaft brackets, and in way of the hawse pipes, where considerable chafing occurs. Further shell plate thickness increases may be found at the panting region .

The uppermost strake of plating adjacent to the main deck is called ‘sheer strake’. As the sheer strake is at a large distance from the neutral axis it has a greater thickness than the other strakes of side shell plating. The upper edge is dressed smooth and the welding of bulwarks to the edge of the sheer strake is not permitted.

The connection between the sheer strake and main deck can present a problem and a rounded gunwale may be adopted to solve this problem where the plating is heavy. This is often the case over the midship portion of large tankers and bulk carriers. The radius of a rounded gunwale must be adequate (not less than 15 times the thickness).

A smooth transition from rounded gunwale to angled sheer strake/deck stringer connection is necessary at the ends of the ship.

All openings in the side shell have rounded corners and openings for sea inlets etc. are kept clear of the bilge radius if possible. Where this is not possible openings on or in the vicinity of the bilge are made elliptical.

Bilge keel

Most ships are fitted with some form of bilge keel, the prime function of which is to help damp the rolling motion of the vessel. Other relatively minor advantages of the bilge keel are protection for the bilge on grounding and increased longitudinal strength at the bilge.

The damping action provided by the bilge keel is relatively small but effective, and virtually without cost after the construction of the ship. It is carefully positioned on the ship so as to avoid excessive drag when the ship is under way. This bilge keel then generally runs over the midship portion of the hull, often extending further aft than forward of amidships and being virtually perpendicular to the turn of the bilge.

Decks

The weather decks of ships are cambered to facilitate the draining of water from the decks in heavy weather. The camber may be parabolic or straight, the latter being preferred in many cases to allow panel lines to be used for the production of the deck panels. There may be advantages in fitting horizontal decks in some ships, particularly if containers are carried and regular cross-sections are desired. Short lengths of internal deck or flats are as a rule horizontal.

Decks are arranged in plate panels with transverse or longitudinal stiffening, and local stiffening in way of any openings. Longitudinal deck girders may support the transverse framing and deep transverses the longitudinal framing.

Deck plating

The heaviest deck plating will be found abreast the hatch openings of the strength deck. Plating that lies within the line of the hatch openings contributes little to the longitudinal strength of the deck and it is therefore appreciably lighter. As the greatest longitudinal bending stresses will occur over the midship region, the greatest deck plate thickness is maintained over 40% of the length amidships and it tapers to a minimum thickness permitted at the ends of the ship. Locally, the plating thickness may be increased where higher stresses occur owing to discontinuities in the structure or concentrated loads.