- Deck girders: These are longitudinal members that combine with the beams to form the longitudinal framing of the deck.

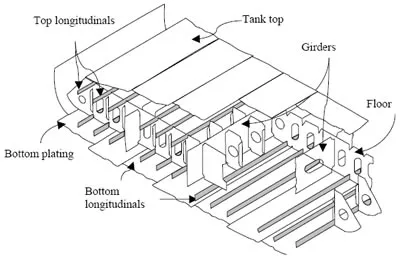

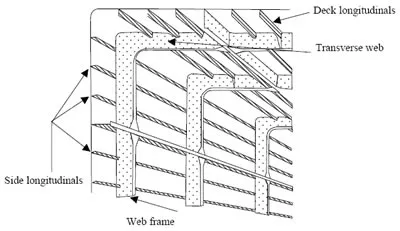

- Longitudinals: A very general term to identify any small longitudinal member that can be used for several purposes. This term is used more specifically in longitudinal framing.

- Web frames: Oversized members that replace a frame at certain locations on a ship.

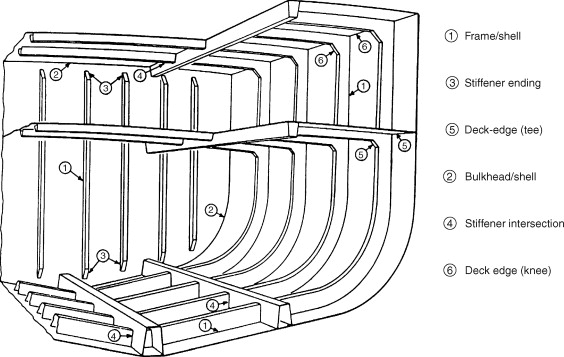

- Bracket: A general term that identifies any part used to connect two members.

- Beam knee: Bracket located at the end of deck beams that connect the beam and frame to the shell plating.

- Pillar: Vertical member inside a ship that connects the deck to the ship’s bottom, where it is installed between two tweendecks, especially around hatches. They are quite bulky and complicate cargo handling inside holds.

- Plating: The plating of a hull is the series of plates that form the watertight shell of the hull. There is bottom plating, deck plating and side shell plating.

- Bilge plating: Longitudinal plating that connects the side shell plating to the bottom plating.

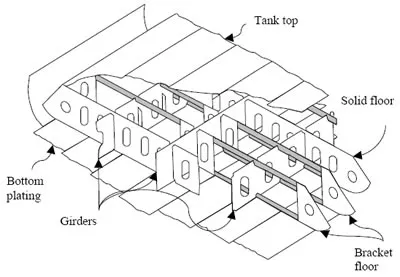

- Tank top: Watertight series of plates attached to a ship’s bottom framework.

- Double bottom: The double bottom is the watertight space between the bottom plating and the tank top. Its height varies according to the size and type of ship, but it is generally between 0.75 and 1.5 metres. A double bottom is divided into several watertight compartments by watertight floors and girders. These compartments can be used to store fuel, oil and ballast water. They are often used to adjust a ship’s list and trim.

A double bottom maintains a ship’s watertight integrity when the bottom is damaged. The tank top greatly increases a ship’s longitudinal strength and forms a platform to carry the ship’s cargo and machinery.

Transversely framed double bottom

Longitudinally framed double bottom