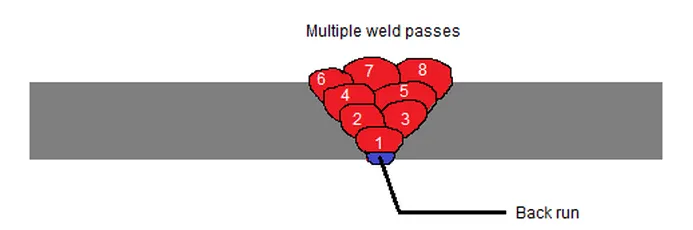

Multiple Passes: When plates of high thicknesses are welded (usually more than 5 to 6 mm), a number of welding passes are required to fill the gap between the plates in order to achieve full penetration. In cases where fillet weld is carried out with high deep bevels between the plates, multiple passes become necessary.

The following figure shows the cross section of a multi-pass butt weld joint consisting of eight passes. Note that the first pass is not sufficient to provide complete penetration till the root of the joint. In order to overcome this, a back run is provided. Back run is an additional welding pass carried out from the opposite side of the weld joint before the main passes are laid. The excess material is then gouged out to obtain smoothness and finish.

Figure 7: Multi-run weld containing eight runs and a back run.

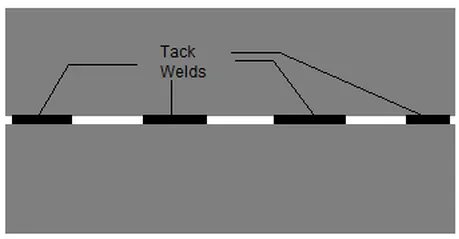

• Tack Welds: Before two plates are welded, they are tack welded at regular intervals along the length of the weld joint. This is done to hold the plates in position, preventing them from opening apart due to heat gradients during the main welding pass. Tack welds are short runs of weld made at intermittent distances, and the electrodes used for tack welds are same as that used in the main runs.

Figure 8: Tack welds before welding of two plates.

• Welding Sequences: Welding sequences are prepared, taking into considerations the distortions that would result. When a weld run is completed, the cooling is not uniform along the length of the weld. This results in the development of stresses that pull the plates closer at one end and pull them apart at the other. In some cases, especially long butt welds, shrinkages occur along the weld length, resulting in warping of the welded plates. In order to minimise these, the sequence and direction of each weld are pre-decided and listed on the welding sequence document of the corresponding structure. They are prepared for welding at all stages, right from the fabrication of panels, units, blocks, to the erection of the fabricated structures on the berth.