Steel:

This is a highly versatile ship construction material and is used extensively on ships for the making of its integral structure and parts.

Steel has been in use for over 150 years in the shipbuilding industry, thanks to its excellent mechanical properties and low cost.

One major drawback of employing steel in ship constructions is the weight of steel.

For the construction of the hull of a ship, mild steel containing 0.15% to 0.23 % carbon, and reasonably high manganese content is used.

Sulphur and phosphorus contents in the mild steel are kept to a minimum (less than 0.05%) as higher contents of each hamper the welding properties of the steel.

Furthermore, cracks and such can develop easily during the rolling process if the sulphur content is high.

High Tensile Steels Steels which have higher strength than that of mild steel are employed in the more stressed regions of large tankers, container ships and bulk carriers. They are often used for the deck and bottom regions of larger tankers as well. As this leads to a reduction in the scantlings of these structural items, it proves advantageous both for the shipbuilder and owner.

Some integral parts of the ship that are made of steel include; the thickness stringer plate, rounded gunwales, sheerstrake, Bilge strake, deck strake in the way of the longitudinal bulkheads, main deck plating, bottom plating, keel, and the upper strake of longitudinal bulkheads. Mast tables, crosstrees, etc., may be fabricated from welded steel plates and sections. Derrick booms, as a rule, are welded lengths of seamless tubular steel.

Aluminium Alloys:

There are three main advantages which Aluminium alloys have over mild steel in the construction of ships.

1. Aluminium is lighter than mild steel and studies suggest that up to 60 percent of the weight of a steel structure can be saved by using Al alloys. For merchant vessels, this is a key advantage for increasing the cargo carrying capacity of ships.

2. Aluminium is highly resistant to corrosion

3. Its non-magnetic properties and low-cost maintenance

The most often used Al-alloys used in shipbuilding are the 5083 type for plates and 6082 for extrusions. These alloys are reliable in marine service as well as during manufacture. It has estimated that the selection of Al-Mg (Aluminium-Magnesium) type alloys brings a potential for at least 10% lower costs in respect of the heat-treatable, and appears favourable after a total estimation for applicability in shipbuilding

Excellent corrosion properties of aluminium can be used easily, but correct maintenance procedures and careful insulation from the adjoining steel structures are necessary when using this material.

A major disadvantage of the use of aluminium alloys is their high initial cost (They are estimated to cost 8 to 10 times the price of steel per tonnage). This high initial cost must be absorbed by an increase in the earning capacity of the vessel or a major increase in passenger accommodation on the same draft.

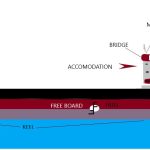

Superstructure

Aluminium alloys can replace carbon steels of normal strength. The weight saved by using Al alloys improves the ship stability – and allows the design of narrower ships, which in turn enhances fuel efficiency.

Comments are closed