Countermeasures against various stresses : It is the shipowner’s responsibility to ensure that his vessel is built to a standard high enough to withstand all the stresses she may be expected to encounter. By their very nature ships are called upon to carry heavy loads, and considerable thought and experience is required to load heavy weights without causing structural damage to the vessel.

Cargo ship unstable in a seaway

Heavy weights tend to cause a downward deflection of the deck area supporting the load .This subsequently produces stresses, with consequent inward and outward deflections of supporting bulkheads, depending on the position of initial loading.These stresses are generally of a localised nature, in the neighbourhood of built-in structures such as windlasses, accommodation blocks etc. and increased scantlings are the norm to prevent excessive distortion.The shipping of heavy seas may add to the load and aggravate the situation, causing unacceptable, excessive distortions.

Another form of stress comes from the water surrounding the ship, which exerts considerable pressure over the bottom and side areas of the shell plating .The pressure will increase with depth of immersion, i.e. the pressure on the bottom shell plates will exceed that on the side shell plates.

Water pressure does not maintain a constant value, and will vary when the vessel is in a seaway, especially when a heavy swell is present. Fluctuations in water pressure tend to cause an ‘in and out’ movement of the shell plating, with more noticeable effects at the extreme ends of the vessel.The effect of water pressure is usually more prominent at the fore end of the vessel than the after end.The general effect is accentuated by the pitching motion of the vessel and is termed ‘panting’.

Panting beams, which are substantial metal beams running from port to starboard, in the forepart of the vessel.They are positioned forward of the collision bulkhead to resist the in and out motion of the shell plating either side of the fore and aft line. Situated at various deck levels, panting beams form a combination with panting stringers on either side in the forepart of the vessel.

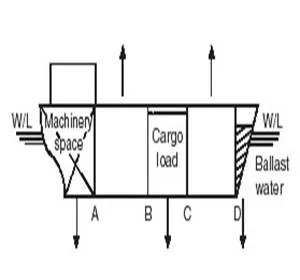

Ships shearing stress

A third form of stress is shearing stress in a material, which tends to move one part of the material relative to another.

The two forces of gravity and buoyancy acting in opposition causes the shearing stress to be experienced at various points in ship. Shearing forces are undesirable within a ship in any shape or form, and prudent loading, together with careful ballast distribution, can reduce them.

Values of stresses incurred during the loading period may be mathematically worked out and then plotted to show the areas of stress by graph. It is worth noting that the mathematical calculations are lengthy, and always leave the possibility for error.‘Stress finders’ and computerised loadicators have reduced the risk of errors. There are several on the market, generally custom made for individual vessels, and they provide the operator with such items of information as:

- Bending moment.

- Shear stress at critical points.

- Mean draught.

- Trim of the vessel.

- GM final, after loading.

- Deadweight.

The information supplied depends on the make and type of software employed.

Comments are closed