Ocean going ships have been using jet engines for marine propulsion since the 1940’s; powering Royal Naval frigates and missile warships, the merchant fleet using them to drive oil tankers and container vessels. Gas turbines have a high power/weight ratio, and can operate on gas or diesel fuel.

We are all used to seeing jet aircraft being driven by gas turbines, but they can also be used as the main engine to propel ships. Gas turbines have been used to propel ships for over forty years, being commercially developed to drive the warship and merchant fleets of all nations. The big advantage of gas turbines over conventional steam turbine or marine diesel main engines is their excellent power to weight ratio.

However the rising costs of fuel has made many ships companies revert back to the marine diesel engine running on heavy fuel oil. In the following sections we shall examine how a gas turbine operates and how it is used to propel modern ships. The first sections provide a look at the components that make up the gas turbine.

Gas Turbine Components

A gas turbine with an output drive shaft is made up of three components.

· An air compressor

· The combustion chamber

· The gas turbine

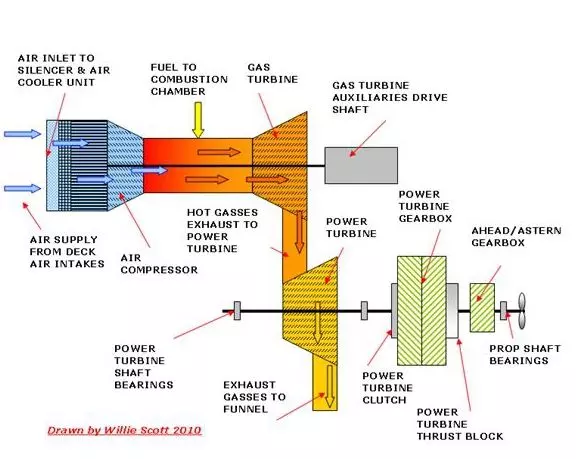

Air Compressor -The air is supplied by an air pretreatment unit comprising of a silencer, an air filter, and an air cooler. The ambient air is drawn through these items of equipment before entering the air compressor. This describes a “multi-stage axial flow air compressor” that compresses the air to high pressure and temperature.

Combustion Chamber -This chamber is situated between the air compressor and the turbine and supplied with gas or diesel oil and the high pressure air. There are numerous fuel nozzles arranged around the combustion chamber, along with two high intensity spark igniters.

Turbine – The hot exhaust gas from the combustion chamber drives the turbine, which is normally of two stage design.

Operation of the Gas Turbine

The unit is rotated using a system like a car engine starter on the drive shaft. Once it is up to operating speed, the gas is introduced to the combustion chamber where it is fired by spark ignition. This further rotates the turbine and the air compressor on the opposite end of the shaft. This compressor draws in air through the silencer and air cooler filter unit, compressing it up to 30 bar before discharging this now high pressure hot air into the combustion chamber and completing the gas turbine sequence, driving the shaft at optimum speed of 3600 revs/min.

Gas Turbine as a Ship’s Main Engine

In gas turbine driven ships, the conventional gas turbine is combined with a power turbine which provides the power to the ships propeller. This system of ship propulsion is known as a “split-shaft gas turbine.”

The gas turbine drive shaft contains the turbine starter and the auxiliary pumps drives for the different systems. Hot exhaust gasses from the gas turbine are fed into the power turbine.

Power Turbine

The power turbine is much slower running than the gas turbine. It has blades and rotors shaped as nozzles similar to that of a normal steam turbine. The power turbine output shaft connects by coupling to the gearbox incorporating a clutch which is used to engage/disengage the drive. The drive shaft exits the gearbox at the revolutions required by either a fixed or variable pitch propeller.

The ship is maneuvered either using the clutch and an ahead/astern gearbox or a variable pitch propeller.

A split shaft gas turbine engine room is much smaller than the normal ship’s engine room, but still contains the fuel and lube oil systems with the associated auxiliary pumps, filters and coolers.

One such system is shown below.

·