The industrial use of chemicals grew massively especially as the wings of globalization and trade spread over the past several decades. Since sea is one of the only methods of transporting goods in bulk quantities across the oceans, it is imperative that the trade of chemicals via the water-route is of vital importance for the industry and global trade. Apart from the different types of ships we have studied thus far, there are ships which specialize in carrying dangerous chemicals across the oceans and they are known as chemical tankers.

Chemical tankers have a history of more than half a century now and initially they were not dedicated chemical tankers but normal bulk carriers carried chemicals in drums. Later on special ships dedicated for chemical trade came into popular use.

What Types Of Chemicals Are Carried?

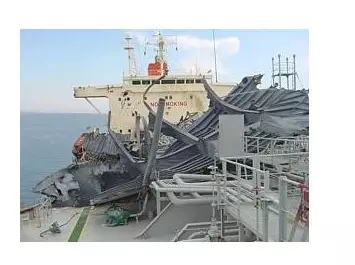

Ships designed to carry chemicals can deal with a variety of products such as oils, fats, petrochemicals, alcohol and so forth. Even synthetic or non-organic chemicals can be transported. These types of cargoes are different from other cargoes in that they have a lot more potential for danger to the men and environment as compared to other cargoes. Such dangers could include flammability, toxicity and corrosive properties of extreme nature. I mean just imagine that you are carrying tons and tons of acid in a tank and roaming around the oceans. That would give you an idea about the types of dangers and precautions required for the same. Just to give you an idea shown below are two pictures of marine accidents caused by chemicals on board.

Types of Chemical Tankers

Even chemical tankers can be of different types such as product tankers and parcel tankers apart from the dedicated chemical tankers. The only difference being that only proper chemical tankers can carry chemicals which are classified as dangerous, while the product tanker can carry both non-dangerous chemicals as well as petroleum goods.

A parcel tanker, as the name suggests, is normally used to carry relatively smaller quantities or parcels of chemicals of different nature, instead of carrying only a specific chemical in bulk. The latter is taken care of by dedicated chemical tankers.

Material of Tanks

You can guess intuitively that since dangerous chemicals are being transported, it is very necessary to provide a proper material for the construction of the tanks otherwise that would result in damage and accidents. I cannot name a single material which is best suited for all situations.

Yet generally speaking it is mild steel or stainless steel. The latter is sturdier than the former against resistance to chemicals; hence mild steel is often coated with anticorrosion paint or a layer of stainless steel for damage prevention.

Inert Gas Plant

We have learnt about the inert gas plant in our previous articles and know that it is necessary to maintain an inert atmosphere inside cargo tanks. Since chemicals are mostly flammable, IG plants are installed on chemical tankers to minimize risk of fire and explosion.

Before a chemical is actually loaded a proper cargo loading plan is made as usual which takes care about the compatibility between the storage tank and the cargo type, apart from other considerations of balance and draft.

Comments are closed