As we sympathise regularly with our readers, running hydraulic systems can be very costly. Not only can costs build rapidly from replacing damaged or worn components, but there is also system downtime to consider and to add to the expense.

If there is one deadly enemy for hydraulics, it’s contamination. In fact, contaminated fluids can be connected to more than 80% of all hydraulic failures. This includes all the related failures that can result including those of hoses, fittings, pumps and valves.

In fact, there is such a strong correlation between contamination of fluid and the lifespan of components that manufacturers of hydraulic and filtration products actually publish charts with the consequence predictions of not having inadequate filtration installed. Those systems that undergo rises in pressure will suffer from even more damage as contaminant particles make their way around the system.

Unfortunately the particles involved in hydraulic system contamination are usually far too small for the naked eye to see them. This is why it’s essential to use instruments specifically designed for contamination monitoring, otherwise a high system reliability cannot be expected to be maintained.

Although the operators and engineers who take care of industrial hydraulic systems are well aware of this problem, it’s only really coming to the fore of the mobile hydraulic system now. In this microcosm of the hydraulic world, there is still some time-based fluid maintenance going on. However, it’s becoming more apparent that this and spin-on filters are no longer enough to keep mobile hydraulic systems operating at their peak performance levels.

Quantifying contamination in hydraulic systems

Ideally every hydraulic system should have absolute filtration to capture both micro particles and those that are larger.

A Beta ratio of filtration will usually capture 99.5% of all particles that could contaminate a system. Alternatively the 1000 measurement will capture 99.9% of the particles. This will support the hydraulic system in enjoying a maximum service life. However, in addition to the Beta ratio, there are other considerations to ponder over when looking to keep the system clean.

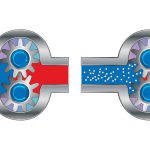

How much dirt a filter can hold and how stable Beta ratio is will determine how well the filtration works out for the system. The best filters are usually cartridge-type that use a number of layers to help to maximise performance for all areas. Each layer will help the filter to either capture the dirt, hold it or to deliver the beta stability.

Another unexpected benefit of the cartridge-type filters is their ability to reduce how much loss of fluid there is when the filter is changed. This can keep go towards keeping costs down, whilst also lowering the impact on the environment. Although the cartridge type filter may cost more to buy, they deliver when it comes to protecting the system and cutting back on fluid loss.

With industrial hydraulic applications, cartridge filters are now considered to be the standard. They are also becoming more popular and widespread in the mobile market, which is becoming more sophisticated when it comes to components in addition to enduring rising costs.

Mobile Filtration Challenges and Solutions

Another area of concern with mobile hydraulic systems is that of space in the system to add filters and other components such as sampling valves. Quite often manufacturers will produce tank-top filters that can be integrated into the hydraulic reservoir, but sit out of the way. With global emission requirements becoming tighter, this trend is likely to accelerate in the coming years.

One issue that is unique to the mobile world is that of the cold start. It’s well known that any hydraulic fluid will thicken when sat at lower temperatures. This can increase the pressure drop for the filter element. The performance will take a downturn until the fluid begins to gain temperature and reaches the operating temperature level. Quite often the comment from an engineer will be ‘I started up and when I hit the level, nothing happened’.

Although it’s possible to install a large filter, it can add to the bulk and the cost of the system. Another work around is bypass the filter by adding in a pressure relief valve until the fluid is warmer. However, this can send contamination downstream. An approach that is less troublesome is to return the fluid to the reservoir as opposed to allowing it to circulate throughout the system.

In summary, as an engineer, the best move you can make is to identify and implement a fine filtration strategy that will enable your hydraulic system to run at its ultimate performance.